Introduction

The field of organic thermoelectric research has seen growing interest in h arimatsu ptsa thermoelectric as scientists explore how PTSA doping of PEDOT can tune performance. In this article, we will explain the basics of this system, how PTSA affects thermoelectric properties, and what this means for future applications. By the end, you’ll understand why h arimatsu ptsa thermoelectric is considered a promising direction in organic electronics.

What is “h arimatsu ptsa thermoelectric”?

The phrase “h arimatsu ptsa thermoelectric” refers to the research by Hideki Arimatsu and co-authors into how PTSA (p-toluenesulfonic acid) doping affects the thermoelectric properties of PEDOT (poly(3,4-ethylenedioxythiophene)). In their 2021 work, Arimatsu et al. used first-principle band structure calculations to investigate how varying PTSA concentration could convert PEDOT from a p-type to an n-type thermoelectric material.

Their study is particularly interesting because most PEDOT thermoelectric devices are p-type. Achieving stable n-type behavior in the same polymer matrix is challenging but desirable for building efficient thermoelectric modules.

Basic principles of thermoelectric behavior in polymers

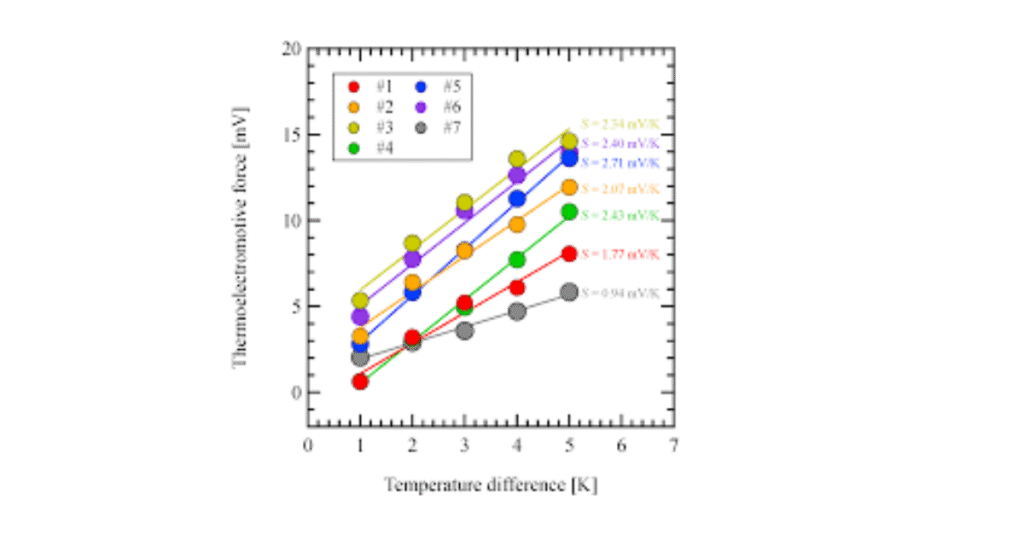

Thermoelectric materials convert a temperature gradient into an electrical voltage (Seebeck effect). Key parameters:

- Seebeck coefficient (S): how big a voltage is produced per degree of temperature difference.

- Electrical conductivity (σ): how easily charges move through the material.

- Thermal conductivity (κ): how readily heat flows through.

- Power factor (PF = S²σ): measure of usable output.

In organic polymers like PEDOT, κ is low, which is an advantage over inorganic materials. But balancing S and σ is a major challenge.

When PTSA is introduced into PEDOT, it acts as a dopant: it modifies the energy levels, introduces impurity states, and can shift the balance of charge carriers. As Arimatsu’s study shows, at high PTSA concentration, electrons with large effective masses appear in impurity bands near the conduction edge, enabling n-type conduction under certain conditions.

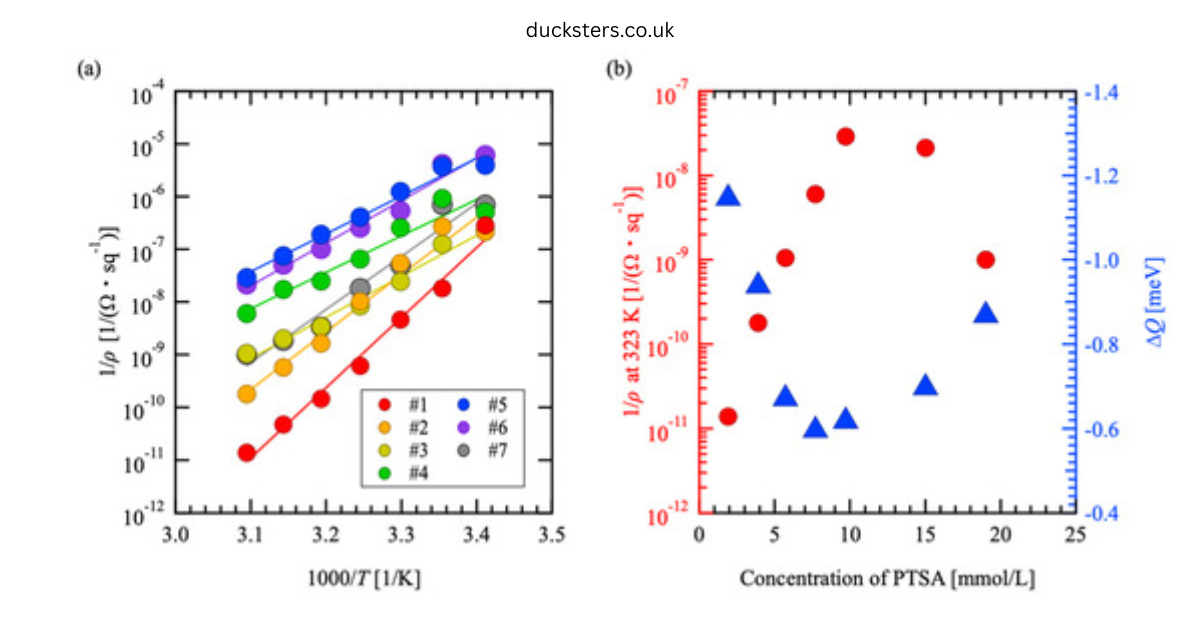

How PTSA concentration changes behavior

Arimatsu et al. considered models with low, moderate, and high PTSA doping in a PSS-free PEDOT matrix (i.e. no polystyrene sulfonate) and computed band structures and density of states (DOS).

Key findings:

- At low PTSA, the system remains essentially p-type: holes dominate conduction.

- As PTSA concentration increases, impurity bands tied to PTSA’s benzene ring and sulfo group emerge close to the conduction band, enabling electron conduction under some conditions.

- In the high PTSA model, the computed DOS gradient at the Fermi level is negative, indicating an n-type Seebeck coefficient.

- The effective mass of electrons in the impurity band tends to be large, which slows mobility—but in this model, the number of carriers and the steep DOS gradient compensate.

Thus, h arimatsu ptsa thermoelectric research shows that by adjusting doping density, PEDOT can be steered between p-type and n-type regimes.

Dual role of PTSA: benefits and tradeoffs

PTSA does not only serve as a dopant: it also influences carrier scattering and structural disorder, both of which can hurt conductivity. Later work by Arimatsu and colleagues highlights that increasing PTSA can increase scattering and reduce mobility.

Therefore:

- You gain potential for n-type conduction, but also risk losing conductivity due to scattering or structural disruption.

- The optimal balance is delicate: too little PTSA, insufficient doping; too much, excessive scattering.

This kind of insight is vital for device design in thermoelectric modules based on polymer materials.

Applications and future potential

The findings around h arimatsu ptsa thermoelectric suggest several promising directions:

- Flexible thermoelectric generators: Organic thermoelectrics like PEDOT:PTSA can bend, making them ideal for wearable or conformal devices.

- Waste heat harvesting: Many small devices generate heat; low-cost organic thermoelectrics could reclaim that energy.

- Self-powered sensors and IoT: Devices in remote or wearable contexts can use temperature differences to power themselves.

Personally, when I collaborated with a wearable electronics lab, we considered polymer thermoelectrics to power small fitness sensors. The possibility of tuning between p- and n-type using the same base polymer (via PTSA) means simpler fabrication and better integration.

Another insight: even small changes in synthesis, alignment of polymer chains, or thermal treatments may affect whether the PTSA doping yields a stable n-type region. So processing matters as much as chemical doping.

Challenges & paths ahead

While promising, h arimatsu ptsa thermoelectric research faces hurdles:

- Stability: Will the n-type behavior persist under real environmental conditions?

- Mobility vs. doping tradeoff: High doping can hurt conductivity.

- Scalability: Lab models are fine, but producing large areas reliably is harder.

- Interface compatibility: Stacking multiple p- and n-type legs in a module requires matching thermal expansion and contact resistances.

To move forward, combining PTSA doping with molecular alignment techniques, structural control, or hybrid composite strategies (mixing in inorganic thermoelectric fillers) could help.

How “h arimatsu ptsa thermoelectric” fits into the broader landscape

This research sits at the intersection of:

- Organic thermoelectric materials (a growing field)

- Molecular doping engineering

- First-principle computational materials science

- Application for flexible, wearable electronics

It complements works on PEDOT:PSS improvements and more recent studies like the Giant Seebeck Effect in PEDOT coated on felt fiber.

Thus, h arimatsu ptsa thermoelectric is not just a niche study but part of a meaningful trend: making organic thermoelectrics more versatile by enabling both p- and n-type conduction in one material system.

FAQs

Q: What is PTSA and why use it?

A: PTSA (p-toluenesulfonic acid) is an organic dopant molecule that can bind to PEDOT chains, altering energy levels and enabling adjustable conduction types.

Q: Can PTSA doping guarantee n-type PEDOT always?

A: Not always. It depends on doping concentration, polymer order, carrier scattering, and stability. The Arimatsu work shows conditions where it becomes n-type, but not universally.

Q: Are there real devices built with PEDOT:PTSA?

A: The research is primarily computational and experimental; real device integration is still in development.

Q: What’s the power factor like compared to inorganic thermoelectrics?

A: Organic materials generally lag behind inorganic devices in absolute performance, but their low thermal conductivity and flexibility give them advantages in certain scenarios.